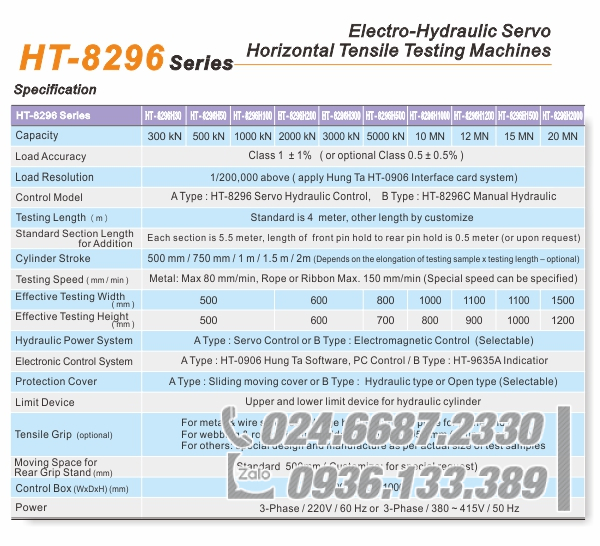

HT-8296 Electro-Hydraulic Servo Horizontal Universal Testing

Machines

| Measurement Device |

| Hydraulic control system or servo control hydraulic system. Apply high accuracy load cell. |

| Testing gain force automatic switching function; if the capacity reach 100%, it automatically witch the large capacity. |

| Accutacy : ≤ ±1% , Load Resolution :1/200,000 above |

| Display a variety of experimental curves:Load-Elongation, Load-Time, Elongation-Time, Stress –Strain. |

| Control System |

| Super powerful control function, with high intelligent computer system |

| testing, application study, force application study. |

| Closed-loop servo hydraulic control system |

| Control Mode : |

| 1. Fixed displacement |

| 2. Fixed velocity |

| 3. Fixed load |

| 4. Constant load speed |

| 5. Constant strain speed |

| 6. Constant stress speed |

| 7.Stress > Strain speed |

| 8. Fixed velocity > Load |

| 9. Fixed velocity > Displacement |

| Fixed velocity control range : |

| Origin point ~ Max. stroke setting range : 0.5 ~ 80 mm/min |

| Control mode of operation : |

| Auto / Manual function available to switch off |

| Emergency shut down button & overload protection (auto stop) functions equipped |

| Setting of testing parameters : |

| Database modularized |

| Accuracy of load : ± 1 % |

| Fixed veloctiy load control range : Full capacity 5 ~ 100% (F.S.) |

| Data Processing System |

| Data acquisition and data-analysis / Clarification. |

| Available to backup and modify the write / read path of database. |

| SI unit and other conversion unit : N, kN, g, kg, ton. lb for force ; mm, cm, inch for length. |

| Self-defined testing modules based upon any kind of standard test norms. |

| Software password security protection ( optional ) |

| X BAR-R engineering diagram and SQC quality control diagram ( optional ) |

| Various kinds of software providing data manipulation and analysis. |